New Upgrade And Experience

The Baby Kangaroo 2.0 Switch has upgraded its light guide pole structure and pins for a better user experience while retaining the highly transparent cover, nylon PA66 milky base, and a bright green POM stem of the original Baby Kangaroo Switch.

Different from conventional tactile switches, the Baby Kangaroo 2.0 switch has a tactile peak point of 0.5 mm to deliver a larger tactile drop for a more evident tactile feel. While the peak point of the conventional tactile switch generally appears at 1-1.5mm, and the bump drop is relatively small. If you are a tactile enthusiast, the baby Kangaroo 2.0 must have a try and you will obtain an extraordinary experience.

Antioxidant Gold Contact Gold Contact

The Baby Kangaroo 2.0 switch adopts original anti-oxidation gold alloy contact which has more reliable conductivity and protects the key switch from corrosion, guaranteeing the switch to last for about 80 million cycles.

Double-stage Gold-plated Spring

This switch incorporates a 22 mm double-stage gold plated spring made of SUS304 material with high durability, which makes the rebound rigid and tight. The spring force tolerance is narrowed to improve the consistency of the feel. Its surface is gilded to preserve oxidation resistance and corrosion resistance.

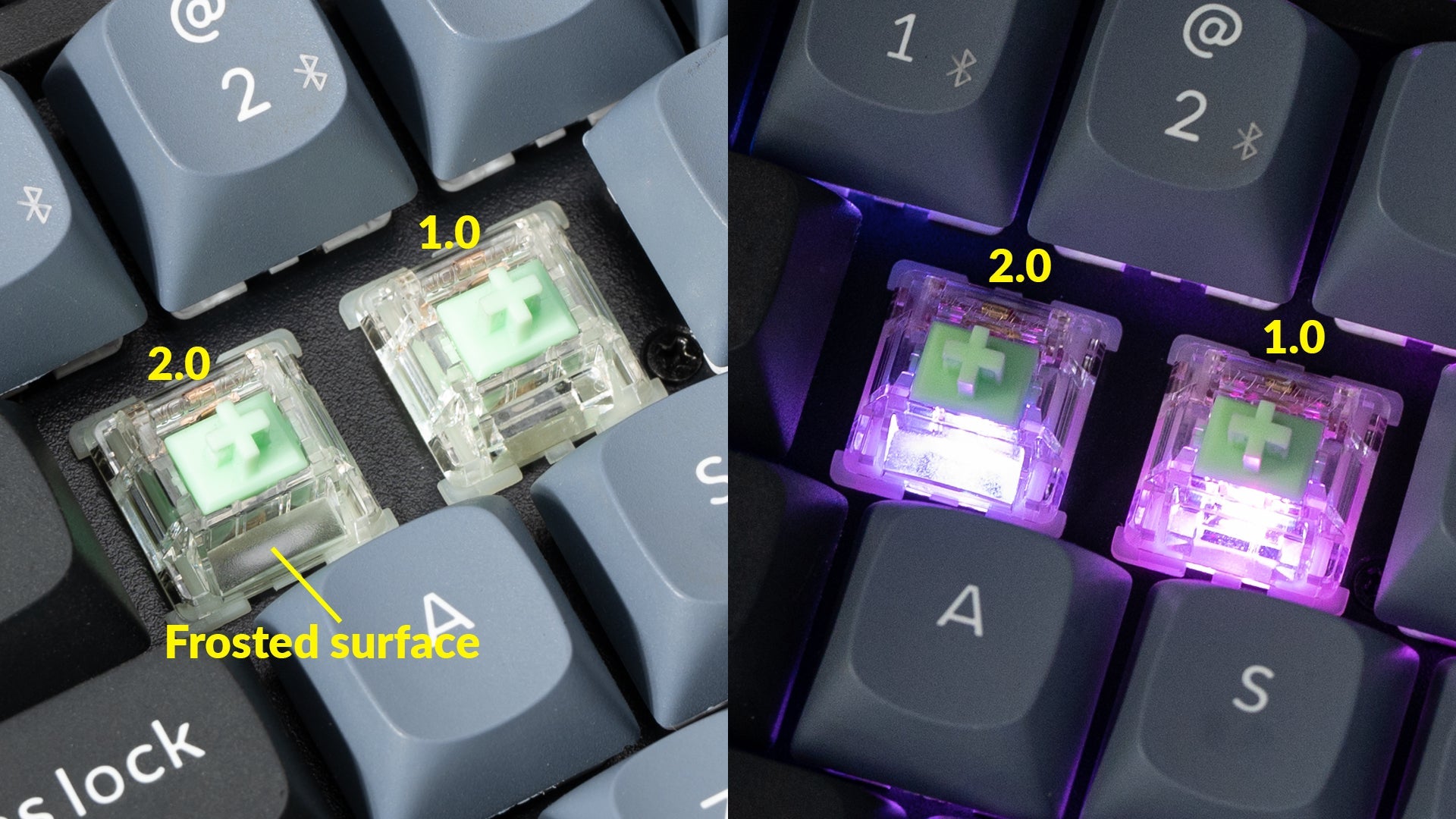

Consistent and Bright Backlight Effect

The upper cover of Baby Kangaroo 2.0 switch keeps the original condenser light effection structure but textures its light guide pole surface to enhance the LED light consistency and brightness.

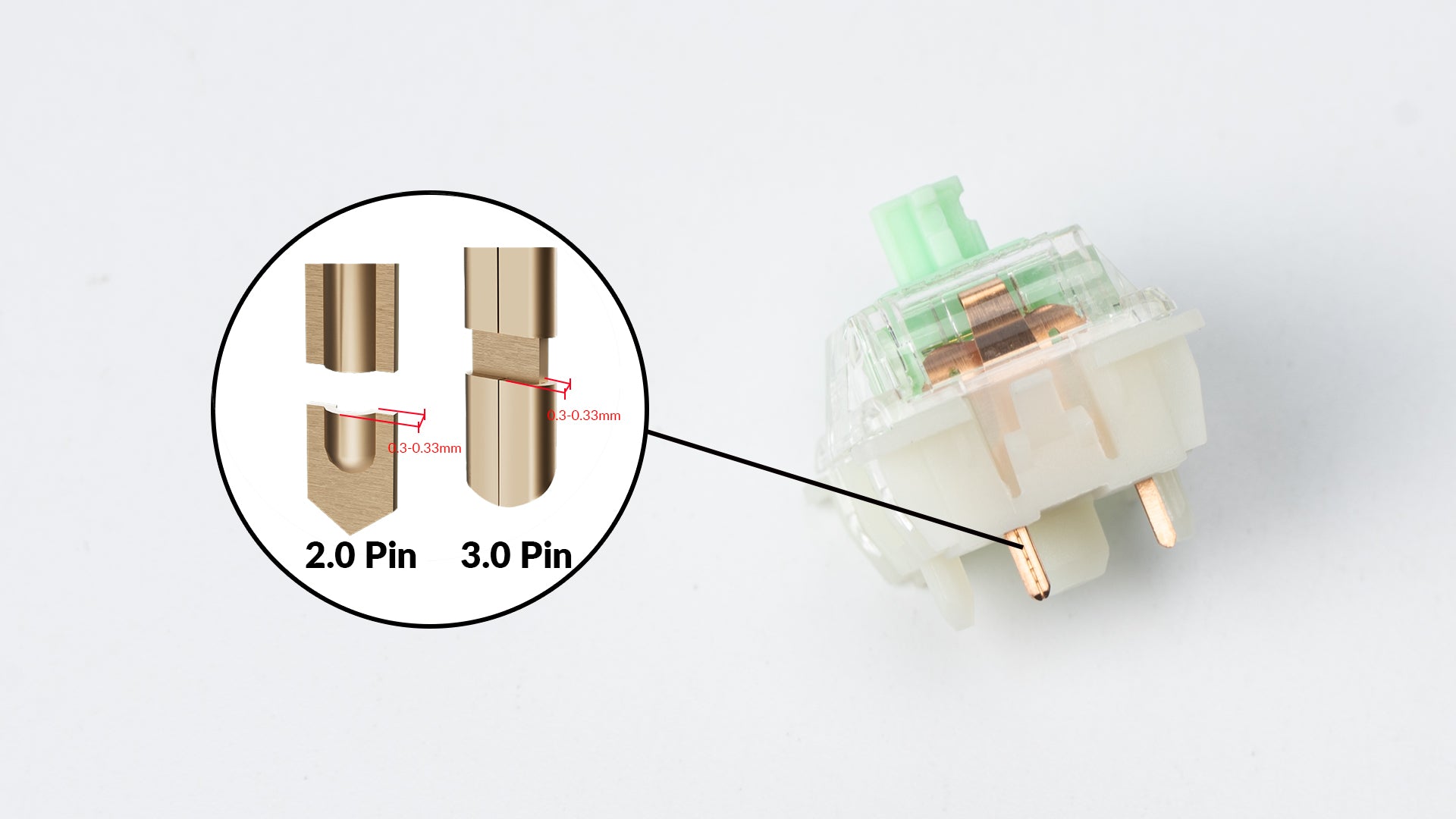

Three-Ply Chunky Switch Pin

The pin is upgraded to 3.0 Pin with a 0.3-0.33 mm three-ply chunky design for a more reliable connection and a longer life span. The stronger pin allows for less damage and deformities and makes it easier to hot-swap.

Automated Factory pre-lubed

Gateron’s automated self-lubricating technology has been continuously optimized for the past 3 years to solve their previous adjustment deficiencies. The CNC fine-tuned its oil injection amount to only 0.1s within 0.001g to not only ensure mass production capacity but to produce a crisper feel too.

![Bridge 75 Plus Keyboard [Pre-order] *LAST BATCH*](http://www.deskhero.ca/cdn/shop/files/blacknorgb.png?v=1722019190&width=104)